Henkel’s TECHNOMELT® Low Pressure Molding Solutions for PCB

Source:Loctite.com / Editor:Ellsworth Adhesive

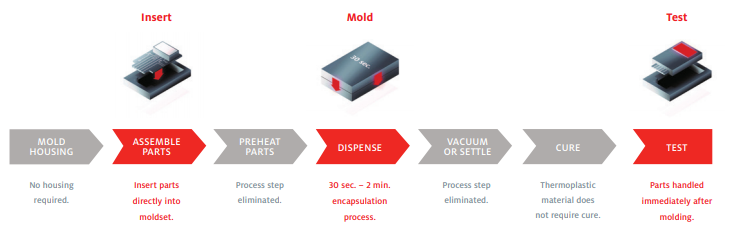

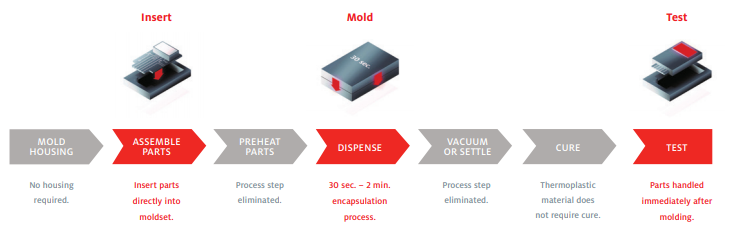

Henkel’s TECHNOMELT® low pressure molding materials are a single-material solution that delivers a simple, streamlined and low-cost alternative to multi-step, multi-material PCB protection methods. A three-step process where parts are inserted into the moldset, molded and tested, low pressure molding eliminates messy two-part material mixing routines, device preparation (masking), long cure times and material waste.

CIRCUIT BOARD PROTECTION TECHNOLOGY COMPARISON

| Traditional CBP Materials |

Material Challenges |

TECHNOMELT Low Pressure Molding Solutions |

| Potting |

● Two-part systems; mixing required

● Non-reworkable

● Large equipment investment and footprint

● 24 – 72 hours cure schedule

● Up to 8 process steps

● 5 – 7 BOM part numbers in inventory

|

● One part; no mixing

● Reworkable

● Weight reduction

● Low waste

● 30 sec. – 2 min. cycle times

● Strain relief

● Green technology; no VOC

|

| Sealing |

● Limited by housing dimensions; space constraints

● 48 – 72 hours cure schedule

● Up to 6 process steps

●5 – 7 BOM part numbers in inventory

|

● No housing; fewer part numbers

● Only 3 process steps

● Improved aesthetic appearance; skylining

● Only 1 BOM part number required

● In-line and high-volume processing

|

| Conformal Coating |

● Very limited mechanical strength

● 4 – 12 hours cure schedule

● Up to 8 process steps

● 3 – 4 BOM part numbers in inventory

|

● No cure

● Temperature, vibration, impact and chemical resistance

● Watertight encapsulation

● Good mechanical strength

● Translucent materials available for optical inspection

|

References: https://dm.henkel-dam.com/is/content/henkel/lt-4182-brochure-technomelt-low-pressure-molding-solutions